news

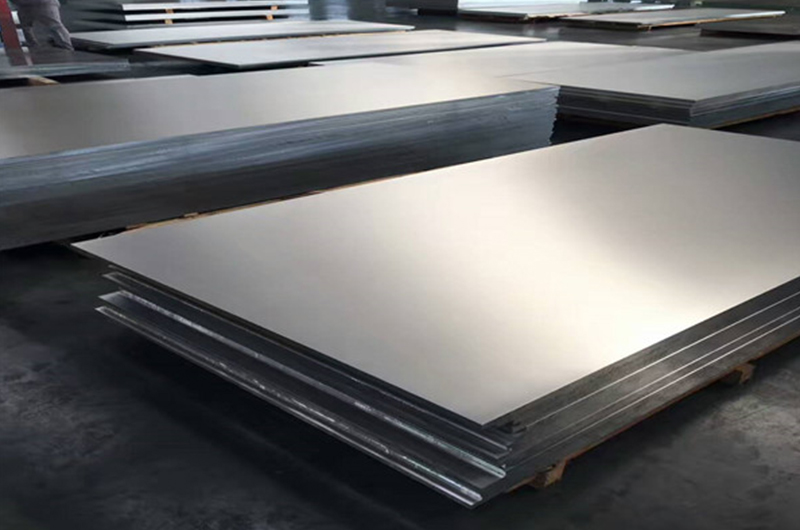

1/4 thick anodized aluminum plate

1/4 thick anodized aluminum plate is to place the aluminum plate in the corresponding electrolyte as the anode, electrolyze under specific conditions and applied current, continuously oxidize the aluminum coil of the anode, and form a thin layer of alumina on the surface, with a thickness of 5 ~ 20 microns. The maximum thickness of anodized aluminum plate can be 3mm.

1/4 thick anodized aluminum plate features:

- Good weather resistance: no discoloration, corrosion, oxidation and rust for long-term indoor use.

- Strong metal sense: the anodized aluminum plate has high surface hardness, good scratch resistance, no paint coverage on the surface, retains the metal color of the aluminum plate, and highlights the high-grade product of modern metal sense.

- High fire resistance: pure metal products, no paint and any chemical substances on the surface, no combustion at 600 ℃ and no toxic gas, meeting the requirements of fire protection and environmental protection.

- Strong stain resistance: no fingerprints are left, stain marks are easy to clean, and no corrosion spots are generated.

- Strong applicability: applicable to metal aluminum ceiling, curtain wall aluminum plate, aluminum plastic panel, fireproof board, honeycomb aluminum plate, aluminum veneer, electrical panel, cabinet panel, furniture panel, etc.

- Small color difference: the aluminum coil is continuously oxidized, so the color difference is well controlled.

Chalco is a professional aluminum oxide plate manufacturer, wire drawing aluminum oxide plate company, which produces various specifications of aluminum substrate manufacturers, with quality assurance and preferential price. Welcome to inquire.