news

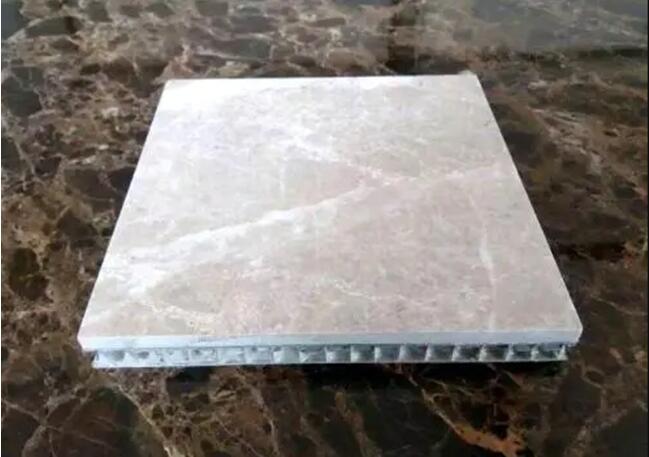

perforated aluminum honeycomb panel

Perforated aluminum honeycomb panel has the advantages of large strength to weight ratio, average stress, strong pressure resistance (the failure pressure is 720kg / ㎡), low thermal conductivity, good seismic resistance, no deformation, light weight, sound insulation effect, and the paper honeycomb core impregnated with chemical glue is not easy to moth and has good elasticity (due to the different density of honeycomb structure in the inner core of honeycomb paperboard, it has a large elastic range and strong seismic resistance). It is an ideal kind of decoration wood materials.

Perforated aluminum honeycomb panel is divided into cushioning honeycomb panel and packaging honeycomb panel according to its function. Due to its special structure, it can improve the compressive strength and reduce the cost of paper honeycomb panel. The pore diameter of honeycomb panel is generally divided into 8mm, 16mm and 32mm, and the weight of paper honeycomb panel is 280g / 1 square meter. Paper honeycomb panel can be used to make all kinds of pallets, liners, packaging boards, packaging boxes, etc. paper honeycomb panel Plate is a new type of green packaging material rising in developed countries this year, which saves resources, protects the ecological environment and has low cost. It has many advantages, such as light, strong, stable, thermal insulation, shock resistance and so on. In terms of volume, it is as small as 0.4 cubic meters and as large as 6 cubic meters. The load is as light as 1 kg and as heavy as 2500 kg.

Perforated aluminum honeycomb panel features:

- High flatness of plate

- Easy and fast installation

- The plate has light weight and high strength

- Plate with large surface

- The honeycomb core material contributes to the thermal insulation effect of the space

- A variety of colors and finishes are available

- High quality materials and advanced processing technology ensure the durability of honeycomb panels